Ultrathin films achieve record hydrogen separation

Metal-organic frameworks (MOFs) are a class of materials that contain nano-sized pores. These pores give MOFs record-breaking internal surface areas, which make them extremely versatile for a number of applications: separating petrochemicals and gases, mimicking DNA, producing hydrogen, and removing heavy metals, fluoride anions, and even gold from water are just a few examples.

In the gas-separation domain, MOFs are particularly interesting for separating hydrogen from nitrogen, which is crucial for clean energy production, fuel cell efficiency, ammonia synthesis, and various industrial processes. Hydrogen-nitrogen separation also has a number of environmental benefits, making it integral to advancing sustainable technologies and industrial practices.

Now, a team of researchers led by Professor Kumar Varoon Agrawal at EPFL’s School of Basic Sciences have developed MOF film with smallest possible thickness that can perform record levels of hydrogen-nitrogen separation. The researchers worked with a type of MOFs known as zeolitic imidazolate frameworks (ZIFs), which have garnered considerable attention for their potential in molecular separations, sensing, and other applications.

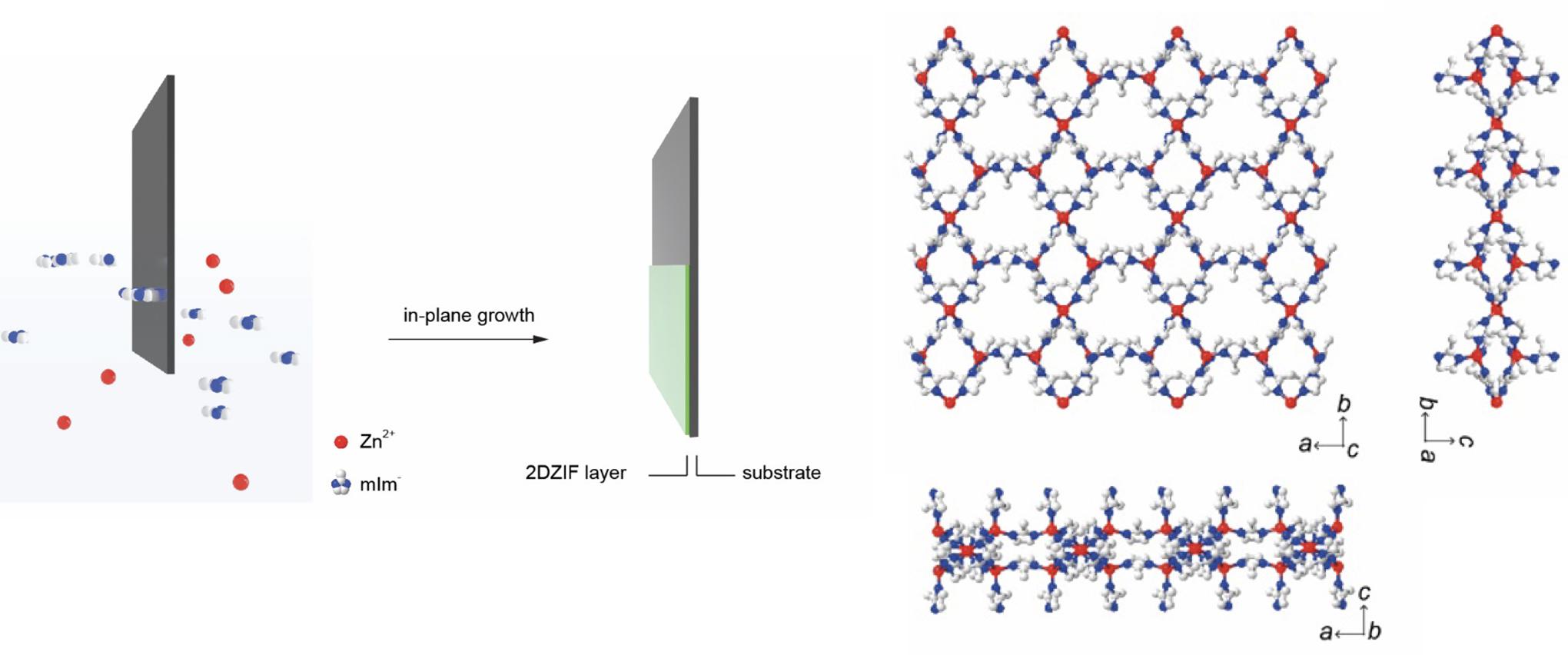

Schematic showing straightforward crystallization of 2d ZIF film by dipping a substrate in ultradilute precursor solution at room temperature (left). Right: Crystal structure of 2d ZIF where white, blue, and red atoms represent carbon, nitrogen, and zinc atoms. Credit: Qi Liu, EPFL.

To make the films, the researchers used an innovative crystallization method that capitalizes on the precise alignment of ultra-dilute precursor mixtures with the underlying crystalline substrate. By carefully controlling precursor concentrations and interactions with the substrate, the team were able to suppress out-of-plane growth – a common problem in making thin films.

The approach paid off: Within a matter of minutes, and at room temperature, the scientists were able to fabricate macroscopically uniform two-dimensional (2D) ZIF films with unprecedented thickness: just one structural unit, measuring only two nanometers. The scientists also showed that the process is scalable preparing films with area of hundreds of square centimeters. The breakthrough overcomes conventional methods, which have limited ZIF film thickness to 50 nanometers, making their widespread use difficult.

The ZIF film has a unique configuration: a nanometer-thick film with a uniform array of hydrogen-sieving six-membered zinc-imidazolate coordination ring. Kumar Agrawal explains: “This allows for an exceptional combination of hydrogen flux and selectivity, holding immense potential for highly efficient gas-separation applications.”