The world’s most powerful neutron microscope

The European Spallation Source ESS currently under construction is in a class of its own, delivering a neutron beam of unrivalled intensity that opens new research opportunities. One of 15 instruments in total being installed at ESS, the ESTIA reflectometer is gradually taking shape. Reflectometers measure reflections or the reflection angles of neutrons at boundary layers and surfaces for non-destructive testing of their properties. PSI is solely responsible for constructing and operating ESTIA. It has just delivered the first part of an important optics component: the Selene neutron guide, which provides a particularly high-intensity beam for investigating material samples.

Neutron sources constitute large research facilities. They provide an intense neutron beam which can be used with different instruments for non-destructive testing of processes and structures on the nanoscale, increasing our understanding of materials. They can be used, for example, to investigate metal components or archaeological artefacts, analyse biomolecular processes or the electronic structure and dynamics of novel superconductors, or solve the remaining puzzles of elementary particle physics. More powerful beams allow even smaller samples to be illuminated, providing even greater detail about the structures and processes within a sample.

The ESS facility produces neutrons through a process of spallation: protons are fired at a tungsten plate, shattering its atomic nuclei and releasing neutrons in the process. This avoids having to use a nuclear reactor – clearly a big advantage. "In addition, we can continue to develop spallation further, which was not possible with the conventional method for producing neutrons dating from the 1950s," says Marc Janoschek, Head of PSI’s Laboratory for Neutron and Muon Instrumentation (LIN) and ESTIA project manager. "It provides a higher intensity neutron beam, and furthermore spallation sources can be operated in pulse mode. In combination, these two characteristics deliver a higher neutron flow with superior temporal and spatial resolution, allowing faster and more accurate measurements."

A large-scale multinational project

A total of 13 nations are involved in the ESS project, each contributing their specialist expertise. Switzerland’s skill set is particularly wide-ranging, as PSI is already experienced in operating this type of facility, having been home to the world’s only spallation neutron source, SINQ, on its research campus for some time. All other spallation sources in service at present work with neutron pulses. Apart from ESTIA, PSI is currently collaborating with other international research institutes on four other instruments being constructed at the ESS: the BIFROST extreme environment spectrometer, the HEIMDAL hybrid diffractometer, the ODIN multi-purpose imaging instrument and the MAGIC magnetism single-crystal diffractometer. PSI is building instruments with a total value of 35 million euros.

PSI researchers and engineers are ideally suited to their role as sole developers of ESTIA since they already operate a very similar instrument in Switzerland: the AMOR reflectometer. Reflectometers shoot the neutron beam specifically at the interface and surface layers of two or more materials. The neutrons penetrate the material and are scattered by their structures. This scattering is captured by detectors and the reflection angles calculated and analysed. They provide information about the composition of the scattering atoms and their arrangement in relation to one another. Because the neutrons interact with the atomic nuclei rather than with the electrons in the atomic shell (as is the case with X-rays), it is even possible to locate and identify isotopes of one material penetrating the other with nanometre precision. Irregularities in a material or a boundary layer can thus be detected with a high degree of accuracy.

Boundary layers are central to understanding many materials and their behaviour in use. For example, the diffusion of lithium ions at boundary layers is crucial for battery performance. In semiconductors, the interfaces of the materials are also important, and in sensors and magnetic storage devices, the magnetic properties of the interfaces play a key role. Even in basic research, exciting and previously unknown phenomena come to light, explains Alessandra Luchini, lead scientist for ESTIA: "For example, two previously non-magnetic materials suddenly become magnetic at their interface, or the superconductive temperature of a superconductor rises from 10 to 100 Kelvin on a specific substrate." This shows that research into magnetic and structural boundary layers is also important for future applications. ESTIA provides the platform for studying these effects on a realistic scale – namely with sample sizes similar to the situations the materials are actually used in.

Swiss precision

The AMOR reflectometer at PSI in Villigen offers extremely high precision thanks to the Selene guide developed in house at PSI. "The intensity of the beam is around 30 times greater than other reflectors," says ESTIA’s head engineer, Sven Schütz. "And when we install this technology at ESTIA in Lund we will be able to boost this power even further."

The Selene focusing guide occupies around 24 metres of the ESTIA instrument, whose total length is 39 metres. Its function is to focus the neutron beam on the sample with even greater intensity. In the past this has been a drawback compared with X-ray microscopes. Modern synchrotron sources enable all samples to be studied on the micrometre scale because their electromagnetic radiation, produced by electrons in strong magnetic fields, is automatically brilliant. By contrast, neutron beams require intense focusing beforehand to study small samples. "With AMOR, we use two 18m-long elliptical neutron mirrors installed in series. These consist of highly polished glass substrates onto which metal layers have been vapour-deposited, which reflect the neutrons," PSI-ESS project manager Artur Glavic explains. This allows the beam to be controlled like a lens to direct the focus onto samples as small as one square millimetre. Without the Selene guide, only centimetre-sized objects could be measured. This is not enough to produce useful information when studying minute items such as computer chips, which are getting smaller and smaller.

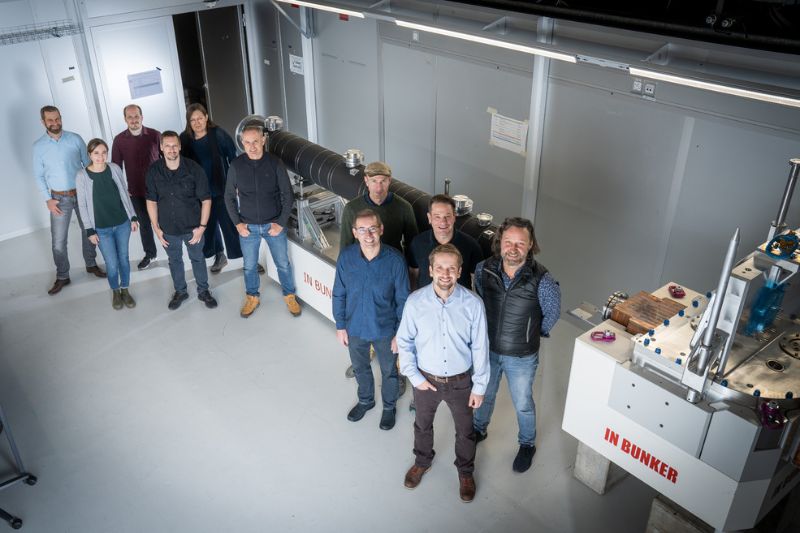

Two trucks transporting the apparatus from Switzerland to the ESS construction site have now arrived in Lund. They constitute the first half of the support frame for the Selene focusing guide. The second part is scheduled for delivery between March and May 2022. Sven Schütz and Alessandra Luchini are supervising installation on site. The guide is fitted with measurement and calibration robots so that it can be remotely controlled within the safety screens, as the installation is under vacuum, and the neutron beam is too powerful for direct intervention. The Selene module is due to be fully integrated by the end of 2022, and ESTIA will be one of the first instruments to start operation at ESS in 2024.

Precision work despite the pandemic

One reason for setting up the instrument well in advance is to ensure greater precision: ESS is built on a complex foundation of concrete pillars which takes time to settle. If the Selene guide is installed soon enough, it will settle at the same rate, eventually providing an even higher degree of accuracy. "Such punctual delivery of the first components was a huge logistical feat and is mainly down to the efforts of Artur Glavic, Alessandra Luchini and Sven Schütz," says Marc Janoschek.

But the effort is definitely worth it. Not just ESTIA in particular, but also ESS as a whole will help advance Swiss research. Switzerland’s State Secretariat for Education, Research and Innovation SERI is contributing 64.5 million euros, or 3.5 percent of the total ESS construction costs of more than 1.8 billion euros. In addition, the running costs amount to some 800 million euros up to 2026, and around 140 million per year when the whole facility eventually goes live. Switzerland will cover nearly four percent of the running costs as well. "Our intention is not simply to contribute our know-how to the operation of such a complex facility," Marc Janoschek comments. "Switzerland also wants to allow its brightest talents access to this large research facility, the only one of its type in the world, so we can continue to be actively involved in leading-edge international research."