Making a femtosecond laser out of glass

Is it possible to make a femtosecond laser entirely out of glass? That’s the rabbit hole that Yves Bellouard, head of EPFL’s Galatea Laboratory, went down after years of spending hours – and hours – aligning femtosecond lasers for lab experiments.

The Galatea laboratory is at the crossroads between optics, mechanics and materials science, and femtosecond lasers is a crucial element of Bellouard’s work. Femtosecond lasers produce extremely short and regular bursts of laser light and have many applications such as laser eye surgery, non-linear microscopy, spectroscopy, laser material processing and recently, sustainable data storage. Commercial femtosecond lasers are made by putting optical components and their mounts on a substrate, typically optical breadboards, which requires fastidious alignment of the optics.

“We use femtosecond lasers for our research on the non-linear properties of materials and how materials can be modified in their volume,” explains Bellouard. “Going through the exercise of painful complex optical alignments makes you dream of simpler and more reliable ways to align complex optics.”

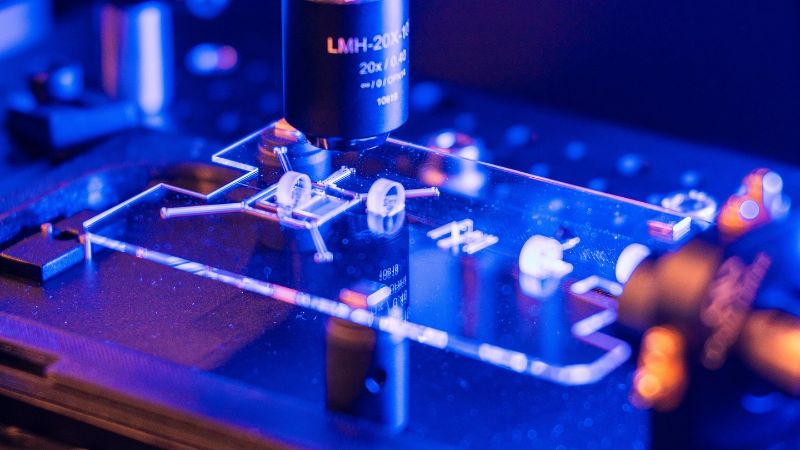

Bellouard and his team’s solution? Use a commercial femtosecond laser to make a femtosecond laser out of glass, no bigger than the size of a credit card, and with less alignment hassles. The results are published in the journal Optica.

How to make a femtosecond laser out of glass

To make a femtosecond laser using a glass substrate, the scientists start with a sheet of glass. “We want to make stable lasers, so we use glass because it has a lower thermal expansion than conventional substrates, it is a stable material and transparent for the laser light we use,” Bellouard explains.

Using a commercial femtosecond laser, the scientists etch out special grooves in the glass that allow for the precise placement of the essential components of their laser. Even at micron level precision fabrication, the grooves and the components are not sufficiently precise by themselves to reach laser quality alignment. In other words, the mirrors are not yet perfectly aligned, so at this stage, their glass device is not yet functional as a laser.

The scientists also know from previous research that they can make glass expand or shrink locally. Why not use this technique to adjust the alignment of the mirrors?

The initial etching is therefore designed so that one mirror sits in a groove with micromechanical flexures engineered to locally stir the mirror when exposed to femtosecond laser light. In this way, the commercial femtosecond laser is used a second time, this time to align the mirrors, and ultimately create a stable, small scale femtosecond laser.

“This approach to permanently align free-space optical components thanks to laser-matter interaction can be expanded to a broad variety of optical circuits, with extreme alignment resolutions, down to sub-nanometers,” says Bellouard.

Applications and beyond

Ongoing research programs at the Galatea Lab will explore the use of this technology in the context of quantum optical system assembly, pushing the limit of currently achievable miniaturization and alignment accuracy.

The alignment process is still supervised by a human operator, and with practice can take a few hours to achieve. Despite its small size, the laser is capable of reaching approximatively a kiloWatt of peak power and of emitting pulses of less than 200 femtoseconds, barely enough time for light to travel across a human hair.

This novel femtosecond laser technology is to be spun-off by Cassio-P, a company to be headed by Antoine Delgoffe at Galatea Lab, who joined the project at a decisive stage with the mission of finalizing the proof-of-concept into a future commercial device.

“A femtosecond laser replicating itself, are we perhaps reaching the point of self-cloning manufactured devices?” concludes Bellouard.