Speeding up materials research with robots

In 2008, Chris Anderson proclaimed “The end of theory” in Wired magazine and claimed in the subtitle that the coming “data deluge” would make the scientific method obsolete. When battery researcher Corsin Battaglia, professor at ETH Zurich and EPFL, shows us his Materials for Energy Conversion laboratory in the new “cooperate” building on the EmpaEawag research campus in Dübendorf, we immediate ly realise that the prophecy has not come true – good old science is still being practised. However, it is obvious that big data and artificial intelligence (AI) are changing the practice of research in a lasting way.

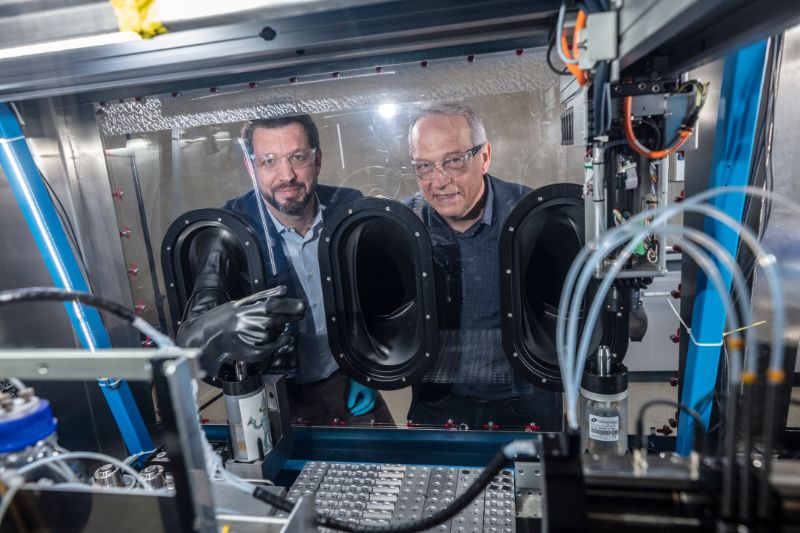

AURORA speeds up battery innovation

People are still to be found in the spacious premises of the Materials for Energy Conversion lab. However, one of the rooms is dominated by a robot: AURORA. AURORA does not look quite like a robot, but more like complex laboratory equipment, with a transparent box that takes up half the room and contains a lot of mechanics, not to mention manipulation gloves. The robot now works very reliably, but at the beginning it needed a lot of attention, according to Battaglia. When it is working without quirks, it patiently goes through various constellations of materials, assembles them into test batteries and records the basic functions of the cells. This is not much different from what Battaglia and his team have already done, just a lot faster. The result is a tenfold acceleration of the test series for material selection, assembly and analysis. It also has significant ad vantages, as the global race is on for new battery materials that are inexpensive, readily available and have no technical disadvantages.

The example of battery research shows a fundamental dilemma of materials science. “If you start with just ten different chemical elements, you end up with more than a trillion possible combinations as a basis for developing new materials,” explains materials scientist Johann Michler, Head of the Mechanics of Materials and Nanostructures laboratory at Empa and professor at EPFL. As if the whole thing was not already complex enough, he also mentions the example of steel. Although it consists primarily of “just” iron and carbon, he says, there are still a large number of steel variants with different properties, “depending on how the steel is heattreated”. It is therefore not necessarily difficult to find new materials – the crux is to pick out the really interesting ones from the jumble of possible materials.

Revolutionizing materials science with rapid analysis

Michler is convinced that the focus of materials science must also be on analytics: “We need to speed up the experimental examination of the material properties: the screening.” He is therefore developing high-throughput analytical instruments that can analyse the internal structure and application-relevant properties of a large number of new materials very quickly. “We don’t measure with the utmost precision, but we do it orders of magnitude faster.” Once you have identified promising candidates, it is sufficient to take a more precise look during the second step. Simple questions and characteristics are of interest in Michler’s work: What colour does a material have and why? And does it possibly have other interesting properties besides a beautiful colour – for example, scratch resistance? If so, the watch industry may well prick up its ears.

Slowly moving from trial and error to AI-based research

What if one could predict all of this? What if AI acquires so much “basic understanding” of solid-state physics that it suggests suitable material combinations and it is no longer necessary to carry out test series after test series more or less “blindly” in search of the needle in the material haystack? Both experts are rather cautious about this. Development is definitely moving in the direction of “physics-informed AI”, but the models are limited, says Battaglia. Even supposedly simple things – such as the voltage generated by a specific battery cell – often prove to be a tough nut to crack. Nevertheless, the battery robot AURORA is expected to gradually learn to work more autonomously. The researchers hope that AURORA will identify patterns and thus the most interesting materials and components depending on the desired battery application.

So, was Chris Anderson right after all, regarding the long-term outlook? Battaglia does not believe that the work of a researcher will soon consist solely of data handling and programming, alone in front of a screen. He believes that it is still good to “have a little hands-on experience”. And Michler adds: “The intuition of the materials researcher comes from working with the material – from having done all the process steps and analyses themselves.”